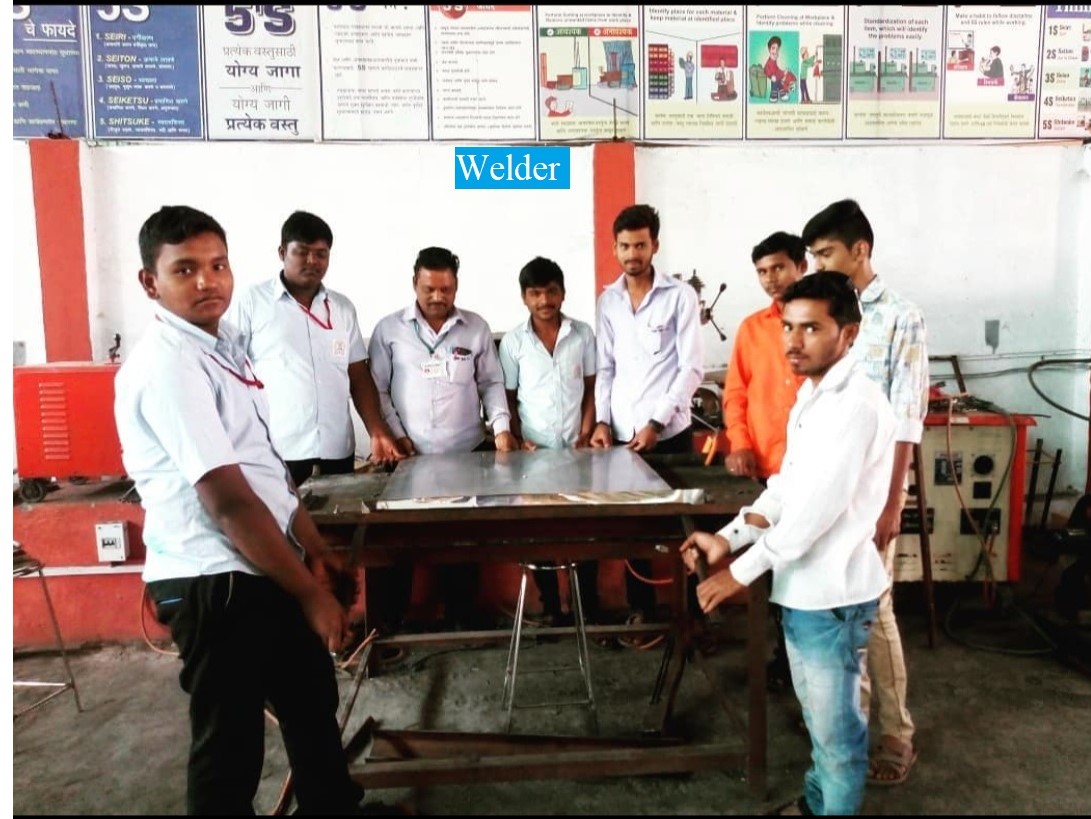

Gas Metal Arc Welder/ Metal Inert Gas/ Metal Active Gas/ Gas Metal Welder (MIG/MAG/GMAW):

Reads fabrication drawing, examines parts to be welded, cleans them and sets joints with clamps or any other suitable device. Connects work piece with earth cable. Connects the machine with suitable gas Cylinder, regulator and flow meter. Connects pre-heater when CO2 is used as shielding gas. Selects suitable wire electrode, feed it to welding GMA Welding torch through wire feeder. Selects contact tip gas nozzle and fit in to the GMA welding torch. Preheats joints as required. Starts the Constant Voltage GMA welding machine, sets suitable welding voltage & wire feed speed and shielding gas flow, produces arc between work piece and continuously fed wire electrode. Melts the metal and deposit weld beads on the surface of metals or joins metal pieces such as Steel, and Stainless-steel metals.

Plastic welder:

Create joint between two thermoplastics by following the steps to any weld; pressing, heating and cooling.

Iron and Steel Plasma Cutter-Manual:

Cuts different materials (mild carbon steel, stainless steel, aluminium, high tensile and special steels, and other materials) in various profiles. This involve setting-up and preparing operations interpreting the right information from the specification documents, obtaining the right consumables and other materials, etc. Plan and organize assigned work and detect & resolve issues during execution in his own work area within defined limit. Demonstrate possible solutions and agree tasks within the team. Communicate with required clarity and understand technical English. Sensitiveto environment, self-learning and productivity.